BREMER VALVES s.r.l

Bremer Valves is a leading company in manufacturing valves. Established in 1947 near Milan by brothers Gianni and Renzo Merlini, with the aim of manufacturing high technology products, in the 60’s BREMER turned its interest to a innovative valve, new at the time: the ball valve. The valves department increased so much that the Merlini brothers decided to switch manufacturing only to ball valves. Since then their products have been continuously updated according to the most modern materials and construction methods. In 1990 BREMER performed their first cryogenic test, which led to an increasing production of cryogenic valves to the point that the company has an inside facility for cryogenic testing.

Services

The spirit of the company is to be strongly custom oriented in order to satisfy all kinds of requests. Flexibility and high expertise allows the development of new products. Bremer Valves is able to satisfy challenging demands for custom made executions, even in small quantities and close time frames.

Phone

+39 031 860906

sales@bremer.it

Headquarters

Via Vignate 3/A

23890 Barzago, Italy

Hours

8am – 5pm

MARKETS

BREMER exports worldwide

and produces valves for different

industrial applications in different markets:

Oil & Gas

Power Plant

Chemical & Petrolchemical

Off Shore Plants

Gas Storage & Cryo Service

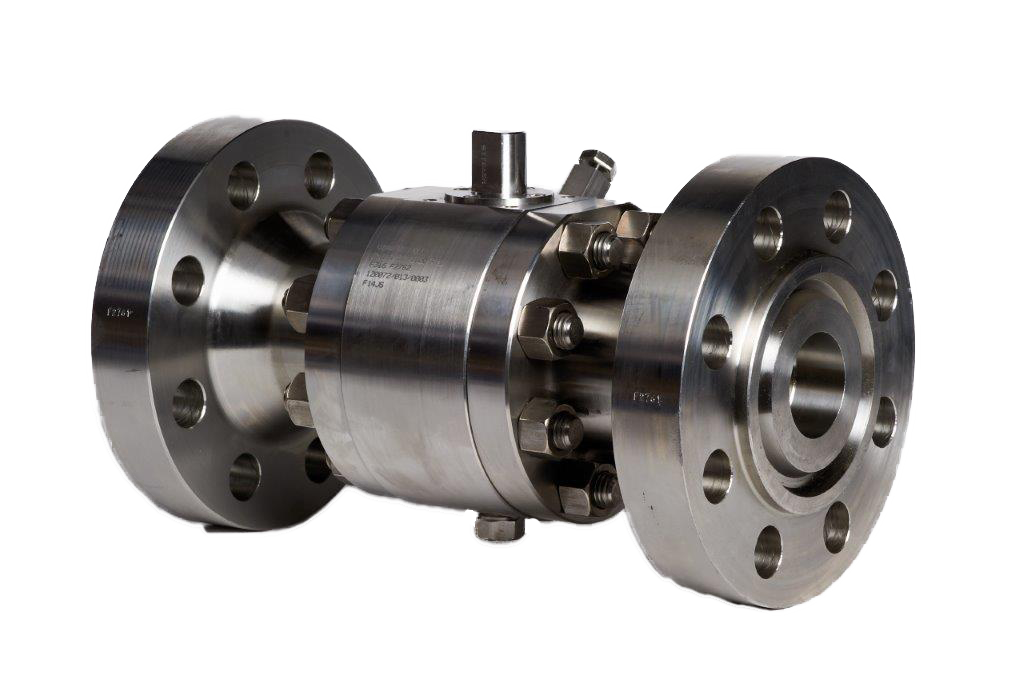

TRUNNION

Heavy design, suitable for high pressure or high size.

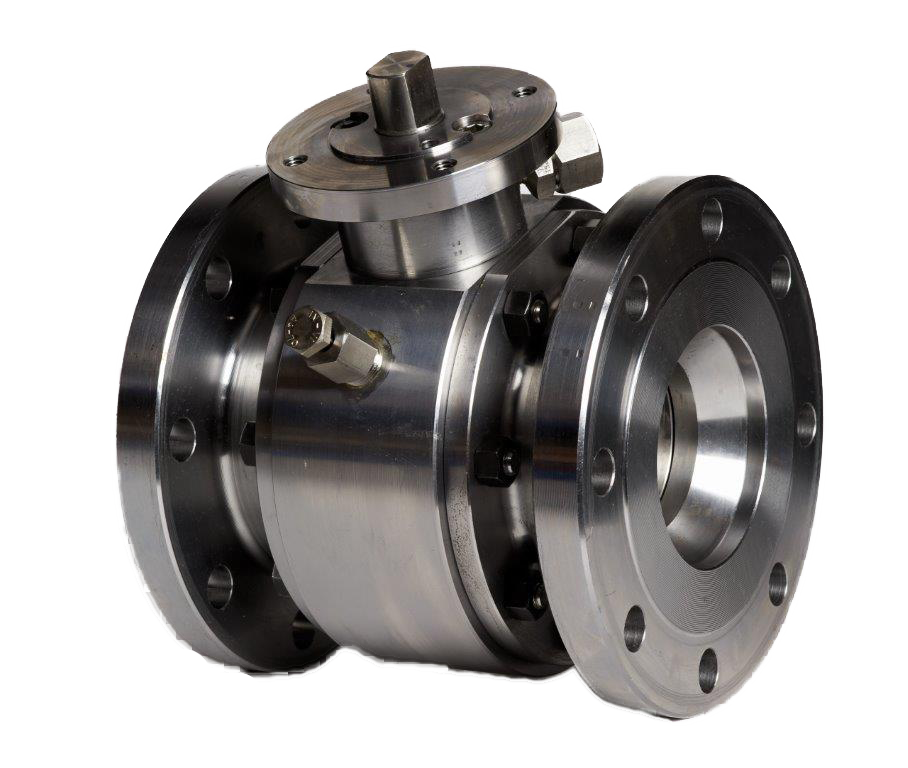

FLOATING

Level control to avoid overflowing. Available with special features.

CRYOGENIC SERVICE

For low temperature, liquefied medium or where safe environment protection is needed.

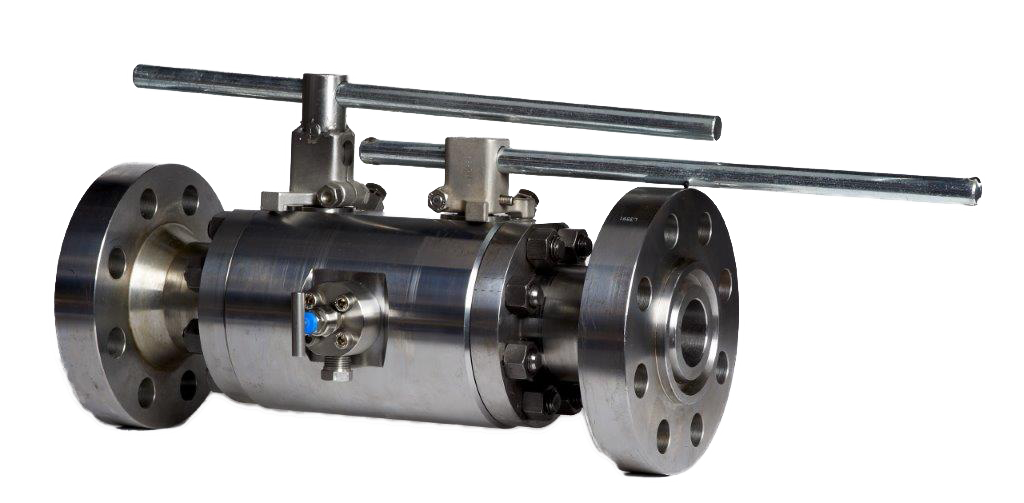

DOUBLE BLEED & BORE

A couple of insulation Ball Valves integrated in a single body.

OUR PRODUCTS

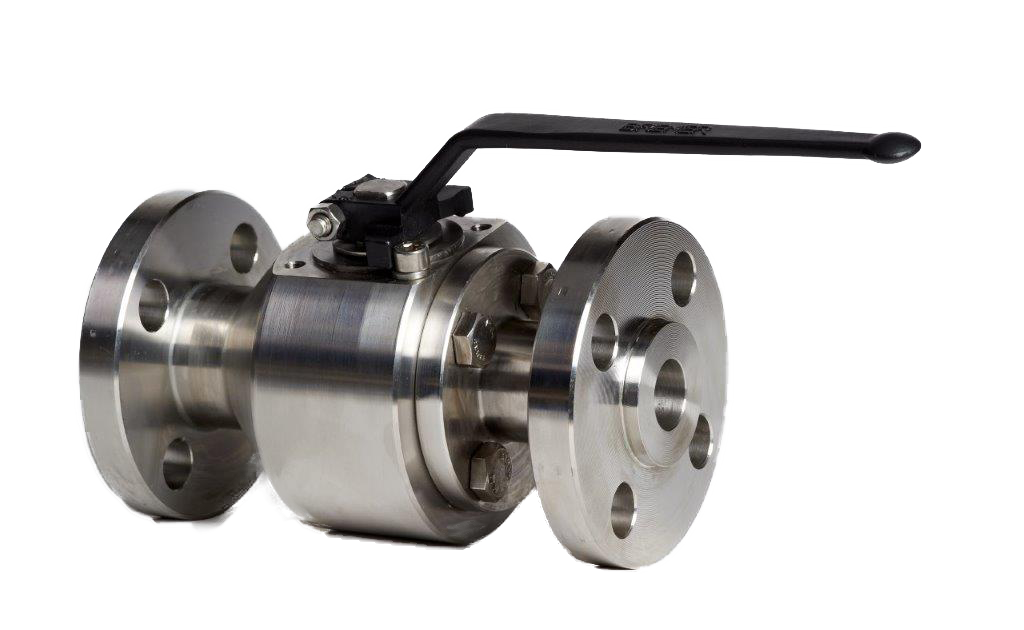

The company has a product range covering floating and trunnion ball valves from ½” to 30”, different pressure classes, executed in standard carbon steel or in stainless steel, duplex, super duplex titanium or exotics alloys for different applications. Ball valves are manufactured for different industrial applications: Oil & Gas, Petrochemical, Chemical, Pharmaceutical, Food industries.

FLOATING VALVES

Floating Valves have a split body with 2 or 3 pieces or wafer, and they can be from ½” to 12″, from class 150 to 2500. The special features are: cryogenic execution and metal seated.

TRUNNION VALVES

Heavy design, suitable for high pressure or high size. The ball is supported by trunnions, so that floating and spring loaded eats are not effected by pressure. Two or three pieces body, API6D design, full and reduced bore, up to 30”, rating up to class 2500, flanged RF, RTJ and BW.

SPLIT BODY DBB

Split body bolted double block and bleed ball valve can be a floating ball or trunnion, with full or reduced bore. Soft and metal seated with a DN from 1” up to 6”, from class 150 up 2500, flanged RF and RTJ. The design can be customized with different materials: carbon steel, stainless steel, special alloys. Standard face to face dimensions according to ANSI B16.10.

BOTTOM OUTLET FLOATING TYPE

Built specifically on request by the customer, this special type of valve is designed and realized to be applied to the bottom of the tanks for the drains in presence of critical temperature, pressure and abrasive products. The project, with an installation totally flat, limits the residual that may remain in the nozzle of the drainage.

CRYOGENIC SERVICE

Floating and trunnion design, for a service temperature up to -196°C. Stem extension, lip seals for oxygen service grease free. Size up to DN 8” and BS6364 tested.

SPLIT BODY 3 WAYS 90º BALL

Split body bolted three ways ball valves, with ‘T’ and ‘L’ port, full bore. DIN flages PN 16-40, face to face dimensions EN-558F1. Floating ball, soft seated with DN 25 to 100, PN 16-40. Antistatic device, fire safe and fully SS AISI 316/1.4401 body and trim.

VACUUM BREAKER & AIR VENT VALVES

With a compact design, vacuum breaker and air vent valves are suitable for clean water, sea water and cooling water. From DN 1” up to 16”, class 150-300, body materials can be: lined carbon steel, stainless steel, duplex,etc. Service: air release, vacuum breaker, air vent, HDPE floating buoy FDA service. With or without spring closing cartridge and adjustable under pressure.

Certifications

Bremer Valves manufactures and assemblies exclusively in Northern Italy following high quality standard attested by:

- ISO9001:2015

- API6D

- PED

- ATEX

- SILII/SILIII

- Fire Safe Certifications BS6755 PART 2

- CRYOGENIC 6364

- TA-LUFT–EPA21

- Seismic Test

Tests

Bremer tests and certifies all valves according to API598, BS6755 part I or DIN3230. Upon request Bremer can perform all the following additional tests, internally or using:

- High Temperature Test

- Low Temperature Test

- Vacuum Test

- Nitrogen Hight Pressure Gas Test

- Fugitive Emission with Helium

- Cycle Test

- Dye Penetrant Test

- Magnetic Particles Test

- PMI

- Ultrasonic Test

- RX Test

CONTACTS

Address

Via Vignate 3/A

23890 Barzago (LC), Italy

Ph. +39 031 860906

Fax +39 031 8624462

Email: sales@bremer.it